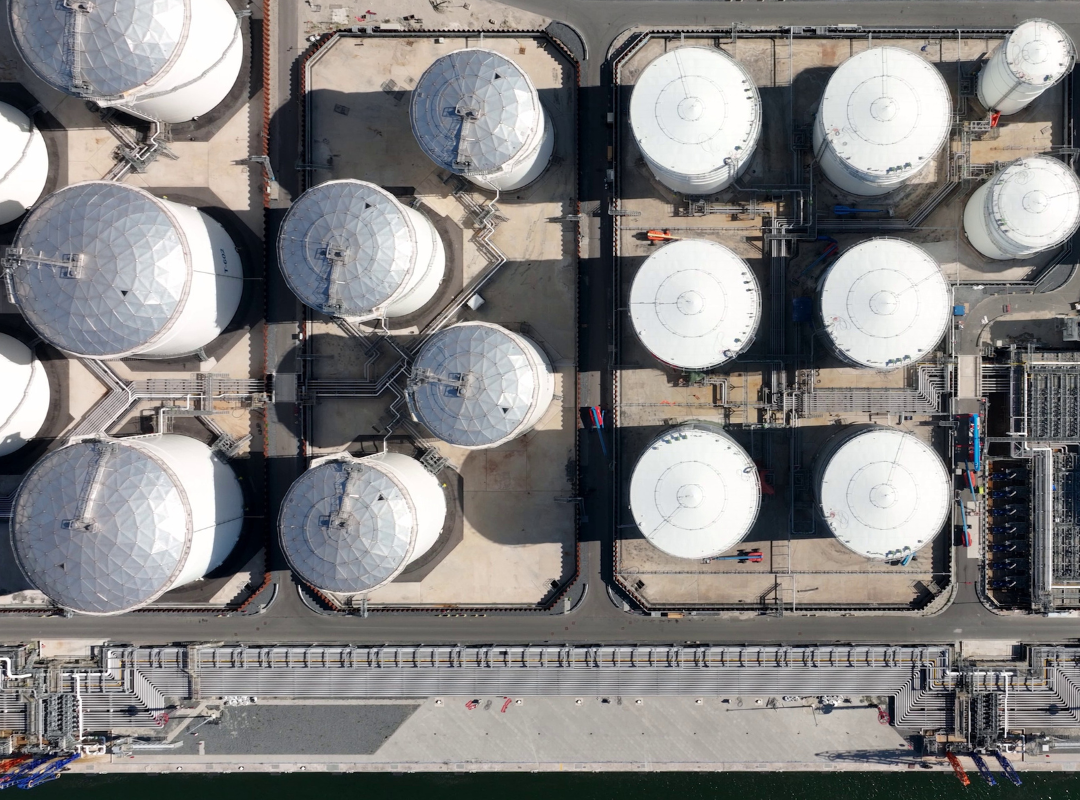

In Saudi Arabia’s demanding industrial sectors—such as oil & gas, water treatment, and petrochemicals—storage tanks are vital components for operational efficiency and safety. The Kingdom’s harsh environmental conditions, characterized by extreme heat, intense UV radiation, and saline air, necessitate the selection of storage tanks that are not only durable but also compliant with stringent regulatory standards. Sherbiny offers engineered storage tank solutions tailored to these unique challenges, ensuring longevity, compliance, and optimal performance.

Key Considerations for Selecting Industrial Storage Tanks in Saudi Arabia

1. Corrosion Resistance

The corrosive nature of Saudi Arabia’s environment, particularly in coastal and high-humidity areas, accelerates material degradation. Selecting appropriate materials is essential:

-

Glass Reinforced Plastic (GRP): Excellent chemical and corrosion resistance.

-

Stainless Steel: Durable and resistant to rust and chemical attack.

-

Glass-Fused-to-Steel (GFS): Combines structural strength with the corrosion resistance of glass.

2. UV and Heat Resistance

Prolonged exposure to UV radiation and high temperatures can degrade tank materials. GRP tanks offer superior performance in these conditions. For steel tanks, UV-resistant coatings and thermal insulation are necessary to maintain structural integrity.

3. Material Compatibility

Ensuring the tank material matches the stored substance is vital:

-

Coated or stainless steel for fuels, chemicals, and pressurized contents.

-

GRP or fiberglass for corrosive chemicals or treated water.

-

Polyethylene for low-risk, ambient-temperature liquids.

4. Capacity and Operational Needs

Tank sizing must account for daily throughput, seasonal storage requirements, and emergency reserves. Undersized tanks can disrupt operations and create safety hazards.

5. Regulatory Compliance

Storage tanks in Saudi Arabia must comply with strict regulatory frameworks. Sherbiny ensures full adherence to:

-

API 650: Standards for welded steel tanks.

-

API 653: Guidelines for inspection, repair, and alteration.

-

Aramco Engineering Standards (SAES).

-

Saudi Civil Defense Regulations.

Sherbiny incorporates compliance from the early design stages through to installation and commissioning. Our familiarity with regulatory bodies and local approvals helps clients avoid delays and ensure inspection readiness.

6. Seismic and Environmental Resilience

In regions susceptible to seismic activity, tanks must be designed with appropriate structural reinforcement, foundations, and anchoring. Environmental risks such as flooding or fire exposure should also be considered in the siting and layout.

7. Maintenance and Inspection

Regular inspection is essential for long-term reliability. Sherbiny employs modern inspection methods including:

-

Non-Destructive Testing (NDT): Ultrasonic testing, magnetic flux leakage, and acoustic emission.

-

Robotic Inspection Tools: Remote-access crawlers for internal wall assessments.

-

Digital Twin Technology: Virtual models for ongoing monitoring and predictive maintenance.

These tools allow for comprehensive assessments without halting operations, improving safety and cost-efficiency.

Tank Type Comparison (Explained Without Table)

GRP (Glass Reinforced Plastic) Tanks are ideal for storing water, wastewater, and chemicals. They offer excellent resistance to corrosion and UV degradation, making them well-suited for outdoor and harsh environments.

Stainless Steel Tanks are commonly used for fuels, process liquids, and corrosive chemicals. Known for their high strength and hygienic properties, they are durable and suitable for demanding industrial applications.

Glass-Fused-to-Steel (GFS) Tanks are often used for storing firewater, effluents, and bulk chemicals. These tanks combine the structural strength of steel with the corrosion resistance of a glass coating, offering long service life and modular construction options.

Carbon Steel Tanks are used for general-purpose storage, including fuel. While cost-effective, they require protective coatings or linings to withstand corrosion, especially in coastal or humid environments.

Polyethylene Tanks are suitable for low-volume storage of water or benign liquids. They are lightweight and economical but typically limited in size and not ideal for more aggressive industrial substances.

Selecting the right industrial storage tank in Saudi Arabia requires a technical evaluation of environmental exposure, material compatibility, regulatory compliance, and lifecycle maintenance. Sherbiny provides complete tank solutions—engineered, fabricated, and supported locally—to meet the highest standards of safety and performance. Backed by our commitment to Vision 2030 and IKTVA, Sherbiny is your trusted partner for industrial storage tanks built for Saudi Arabia’s most demanding applications.

For engineering support or to discuss your project requirements, contact Sherbiny.