In high-risk industrial environments—particularly in oil & gas, petrochemicals, and energy facilities—gas detection is a critical safety requirement. With over 40,000 gas detection systems deployed across Saudi Arabia, Sherbiny is a trusted leader in safeguarding lives, assets, and operations. This article explores the types of gas detection systems, key technologies, deployment strategies, and the value of long-term technical support, tailored specifically to the industrial context of the Kingdom.

The Role of Gas Detection in Saudi Industry Saudi Arabia’s industrial plants operate in environments where flammable, toxic, or oxygen-displacing gases pose significant hazards. Uncontrolled leaks can result in fires, explosions, or serious health risks. Regulatory compliance is governed by Saudi Civil Defense, Aramco Engineering Standards (SAES), and international codes such as IEC, ATEX, and NFPA.

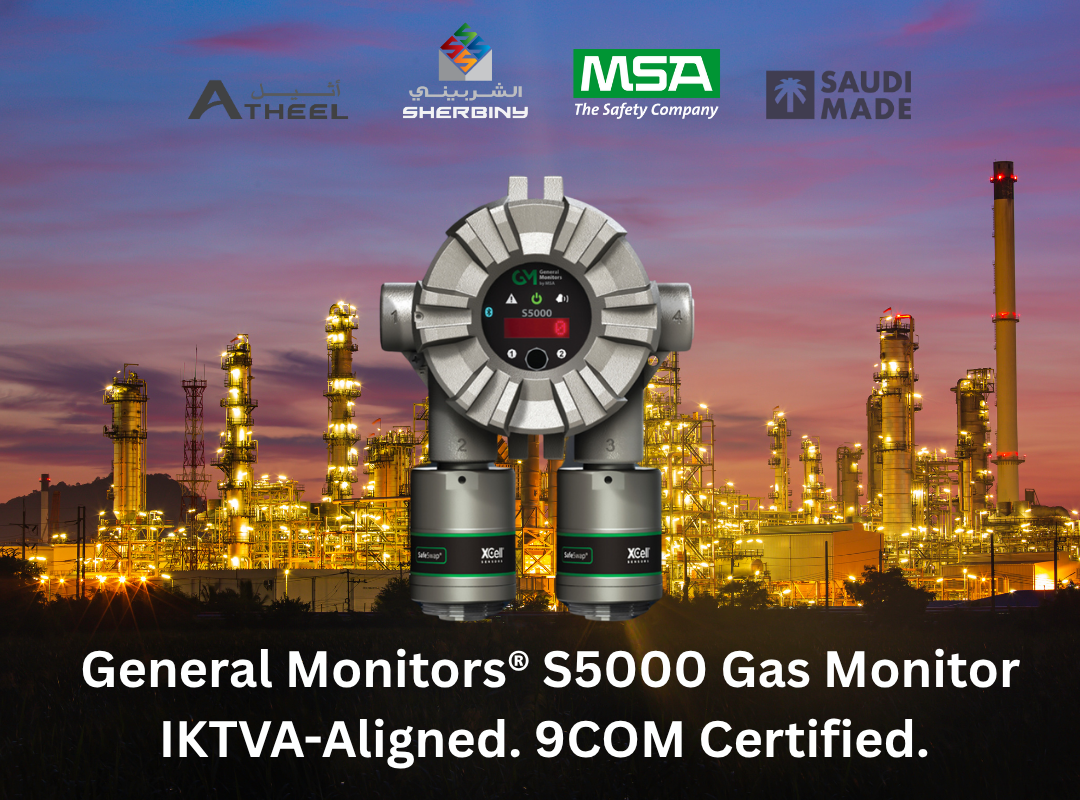

Sherbiny, as a 9COM-approved vendor for Saudi Aramco, ensures that all supplied gas detection solutions align with the highest regulatory and performance benchmarks.

Core Types of Gas Detection Systems

Point Gas Detectors

Used to monitor gas concentrations at fixed locations. These are ideal for enclosed areas or specific leak-prone zones. Technologies include electrochemical sensors for toxic gases and catalytic bead sensors for flammable gases.

Open Path Gas Detectors

Deploy an infrared beam between transmitter and receiver to detect gas over a distance. Suitable for perimeter security and wide-area industrial zones.

Flame Detectors

Monitor optical signatures from combustion. UV, IR, and multi-spectrum flame detectors provide rapid response in case of hydrocarbon fires or flash fires.

Toxic Gas Detectors

Detect dangerous gases such as H2S, CO, Cl2, or NH3. Electrochemical cells provide high accuracy and sensitivity.

Combustible Gas Detectors

Monitor for explosive gases such as methane or propane. Two leading technologies include:

-

Catalytic Bead: Cost-effective, sensitive, but requires oxygen to operate and regular calibration.

-

Infrared (IR): More durable, requires no oxygen, immune to sensor poisoning, and ideal for remote or harsh environments.

Technology Focus: General Monitors® S5000 Sherbiny locally manufactures the General Monitors S5000, one of the industry’s most advanced fixed gas detectors. Key features include:

-

Dual sensing support: Monitor two gases simultaneously.

-

Bluetooth and Modbus/HART integration: For real-time diagnostics and remote configuration.

-

SafeSwap™: Enables sensor replacement without powering down.

-

XCell® sensors: Optimized for longevity and stability in fixed applications.

-

TruCal™ technology: Reduces calibration frequency while improving accuracy.

Best Practices for Gas Detection Deployment in Saudi Plants

-

Hazard Mapping: Use gas dispersion modeling to identify optimal sensor locations.

-

Redundancy: Combine point and open-path systems for layered safety.

-

Environmental Adaptation: Ensure detectors are rated for high heat, sand, and corrosive conditions.

-

System Integration: Connect gas detectors to SCADA, shutdown systems, and fire suppression.

Long-Term Value Through Local Support Sherbiny’s differentiation lies not only in product delivery but in full lifecycle support:

-

System design tailored to Saudi plant environments

-

IKTVA-compliant local assembly and stock

-

Technical support and field calibration services

-

Spare parts and maintenance contracts

-

Training programs hosted in Riyadh and Eastern Province

Gas detection systems are not a procurement formality—they are a strategic safeguard for industrial resilience. With proven deployment in Saudi Arabia and in-house expertise backed by 9COM approval and local manufacturing, Sherbiny offers a reliable path to regulatory compliance and operational safety.

To consult with Sherbiny’s safety systems experts or explore our MSA-certified portfolio, contact us.